Watch Video

While the fledgling Triple Bottom Line (People, Planet and Profit) movement may not yet be the mainstream causecélèbre its proponents and early adopters hope it will become, its underlying notion of building a healthier and more sustainable world through responsible choices on everything related to food—from farming to consumption— is an idea that millions of Canadians could easily get behind. In fact, many of them have already done so for the better part of the 21st Century—consciously or not—by switching to organic, minimally processed food sources that naturally promote healthy eating and nutritional habits, with minimal impact on the environment.

While the fledgling Triple Bottom Line (People, Planet and Profit) movement may not yet be the mainstream causecélèbre its proponents and early adopters hope it will become, its underlying notion of building a healthier and more sustainable world through responsible choices on everything related to food—from farming to consumption— is an idea that millions of Canadians could easily get behind. In fact, many of them have already done so for the better part of the 21st Century—consciously or not—by switching to organic, minimally processed food sources that naturally promote healthy eating and nutritional habits, with minimal impact on the environment.

Founded in 2005, Montreal-based company PRANA Biovegan Inc. is a bona fide corporate poster child for the 3Ps business model that embraces integrity, transparency, and social and environmental responsibility at the core of its everyday business operations. Co-founded by the husband-and-wife team of Alon Farber and Marie-Josée Richer, who met each other while backpacking through India about 20 years ago, the company is one of Canada’s fastest-growing processors of organic snack products such as nuts, seeds, dried fruits and berries, cocoa, granola and trail mixes, and other plant-based vegan foods sourced from around the world. Sorted, processed and packaged at the company’s SQF-certified, 60,000-squarefoot production facility in the Montreal suburb of Saint-Laurent, the PRANA brand organic products are nowadays readily available across Canada at most leading supermarket chains and independent grocers, in addition to being distributed as private-label store brand offering throughout major Canadian and U.S. markets.

Such fairly quick rise to market prominence is especially impressive in light of the company’s humble origins and early days. After arriving to Canada from India in 2005, Farber and Richer decided to open up their own business specializing in fresh hummus, tofu, hazelnut spreads and ready-to-eat vegan dishes, which they would cook at home and hand-deliver to local specialty restaurants, health-food stores and farmer’s markets. At a time when organic foods were still a very narrow market niche across North America, the fledgling start-up had a hard time getting significant capital backing from potential investors, Farber recalls, prompting its co-founders to strive to become entirely self-sufficient through hard work and word-of-mouth marketing.

Despite all its limitations and challenges, the company managed to generate about $100,000 in revenues in its first year of operation, according to Farber, growing to about $250,000 in its third year. “It was all work seven-days-a-week in those early days,” says Farber, adding the couple originally used Richer mother’s kitchen to create the earliest products, before renting out space at the back of a local coffee shop. “Not having access to a lot capital was definitely a disadvantage,” he notes, “but it also had the advantage of forcing us to learn to be frugal and not be too shy about putting in real hard work. “So it was a really good learning experience that way.” But after three years of hard aroundthe-clock wok, Farber and Richer decided they would need to change the company’s product portfolio and market focus to grow the business further. “After couple of years we realized that making and managing all these perishable products was a complicated endeavor that required a much more sophisticated supply chain than what we had,” says Farber, “so we decided to get out of the perishables to concentrate on selling non-perishable organic foods.” With solid knowledge of the agricultural business obtained from growing up and being raised on a farm in his native Israel, Farber put that knowledge to work by identifying and sourcing the organic nuts, seeds, fruits and other ready-to-eat crops that would appeal to the growing segment of population becoming more aware and better-informed about organic food production in general.

Around the same time, the company hooked up with a major local food distributor in a partnership aimed at expanding its customer base. “Our ability to continue our growth trajectory and reach more customers was limited without expanding our distribution network,” Farber explains, “so it was important for us to start looking elsewhere. “They asked us if we could supply them with some packaged nuts, seeds and dried fruits,” he recalls, “and that quickly became an important business focus.” Says Farber: “Right from the beginning, we had the mindset to supply products that would provide a responsible alternative to the food choices available to consumers in Canada. “That became our mission,” Farber asserts, “and we were lucky in the sense that the health-food movement was just beginning to get traction here in Quebec, and across Canada, to drive growth in demand for cleaner, organic products. “Hence, we wanted to position ourselves as a brand that cares about the environment; cares about the quality of nutrition consumers get; cares about the suppliers, the farmers and everyone else in the supply chain—all the things that we believe are important. “It was hard work to get the message out,” he says, “but it all paid off by resonating with the Canadian consumers.”

It certainly has, with sales of the company’s flagship PRANA Organic brand not only catching fire across Canada since its 2005 launch, but also earning a fast-growing market share in the U.S. With keen focus of continuous product innovation and experimentation, the PRANA Organic brand family itself has grown exponentially over the years to comprise dozens of different product blends and flavor varieties. Packaged primarily in high-quality resealable plastic stand-up pouches incorporating high-impact product photography and imagery of the many exotic healthy foods and ingredients used to make the product, the PRANA product portfolio covers a broad array of inspired and unique offerings ranging from granola bars and chia seeds to varied trail mixes, salty and savory snacks, chocolate treats, cookies, dried fruits and many other imaginative snack-food creations. As one of the earliest Canadian food businesses to receive the vaunted global B Corp certification for “meeting the highest standards of verified social and environmental performance, public transparency, and legal accountability to balance profit and purpose,” PRANA goes through great lengths to ensure that the lion’s share of all the different raw ingredients it sources worldwide meet its exacting criteria for non-GMO origins, Fair Trade practices, ethical working conditions, and minimal carbon footprint.

Not surprisingly, PRANA’s earnest and genuine commitment to environmental sustainability applies to everything that unfolds on the production floor of its new production facility in Saint-Laurent, where the company moved in 2019 to accommodate its growth plans. Aiming to become a food waste-free facility by the end of the year, the modern high-ceiling facility houses three packing lines and 80 full-time employees working on a two-shift, five-day weekly production schedule to churn out ever-growing quantities of the company’s branded and private-label products. With one line dedicated to pillow bags and second one to stand-up pouches, the plant employs two fully-automatic multihead weighscales and two high-performance vertical pouch bagging machines running at average speeds of up to 120 pouches par minute. Until recently, the relatively high level of automation at the front end of the process presented a real challenge for the downstream personnel at the end of the stand-up pouch line, who were tasked with the grueling and repetitive jobs of removing the incoming pouches off the conveyor belt and placing them inside the corrugated shipping carriers used to ship the product to customers. Employing up three people to keep up with the product flow, the manual process was in dire need of a switch to more automated mode of operation, according to Farber, to enable better line efficiencies and a more productive use of the company’s personnel to perform more value-added tasks elsewhere in the plant. “With the cost of labor becoming more expensive, and finding people to do these kinds of jobs becoming harder to find, end-of-line packaging has been an area of concern for some time,” Farber acknowledges. “The whole COVID pandemic experience only accelerated our need to invest in additional automation.” Buoyed by substantial government assistance from the Quebec Ministry of Agriculture, Fisheries and Food (MAPAQ) as part of the ministry’s Food Transformation Program: Robotization and Quality Systems, Farber finally had the required funding in place to address the end-of-line shortcomings. Before long, Farber approached renowned local packaging machine-builder Paxiom Group to find an effective way to automate the end-of-line packaging process for the stand-up pouch line. “We looked around and it seemed that no one had the machine we needed to take care of our specific requirements on that line,” Farber recalls. “But with Paxiom being a local company, we felt comfortable to work with a local partner to develop a solution that would meet our needs.”

Happily for PRANA, his hunch to engage Paxiom as a partner in this endeavor turned out to be a perfect call. As Paxiom’s territory manager Andre Strul recalls, “Their main objective was to reduce the number of employees hand-packing the product off the line, and thus avoid having them do repetitive motions all day long. “Moreover, their existing hand-packing method allowed them very little control over their pouch alignment and feeding consistency, as well as quality of their corrugate boxes,” Strul adds. “Being a local company, we were happy to take on the challenge of offering them cutting-edge technology to resolve their issue.” Installed on the stand-up pouch line’s downstream area just past the METTLER TOLEDO combination metal detection/checkweighing station, the customized turnkey packaging solution provided by Paxiom is actually a fully-integrated turnkey system comprising three high-performance packaging machines manufactured by two different Paxiom manufacturing sister companies, Valtara SRL in Italy and EndFlex LLC in the U.S. Installed and commissioned about four months ago, the fully-automatic turnkey

solution incorporates:

solution incorporates:

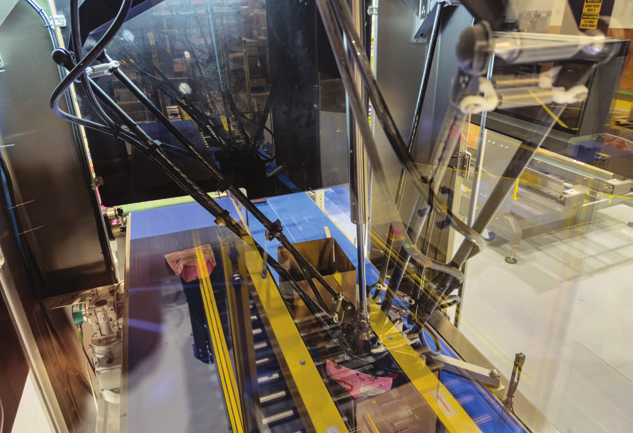

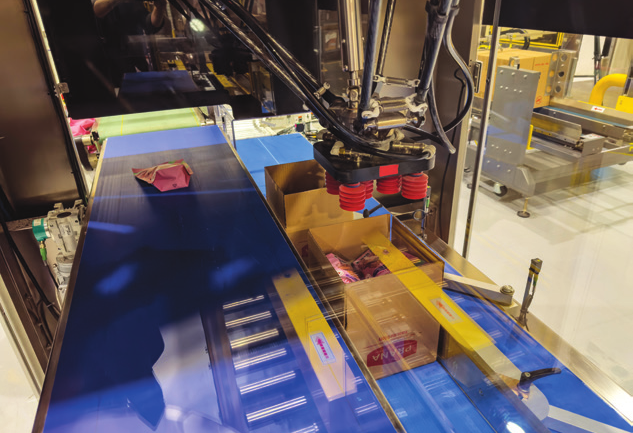

• The PKR Delta 1300 modular robotic pick-and-place workcell supplied by Paxiom’s Italian-based sister manufacturer Valtara.

Designed for automatic top-loading of flexible bags and pouches into corrugated case or trays, the servo-driven system can be integrated with any case or tray former to reduce labor costs by eliminating manual packing stations, according to Paxiom. Boasting a compact footprint that easily fits into any packaging line for precise top-loading of products in single or multiple layers, the PKR Delta 1300 is designed to provide exceptionally gentle product handling with vacuum or mechanical product pick-up to ensure optimal product integrity and consistent case/tray loading in a wide variety of sizes and pack patterns. Deploying a multi-axis Delta robot capable of up to 80 picks per minute—depending on weight, distance, product and pack style—the PKR Delta 1300 is fully outfitted with advanced Omron controls, electronics, sensors, HMI (human-machine interface) control terminal, smart machine vision camera, and other essential automation componentry for optimal machine performance.

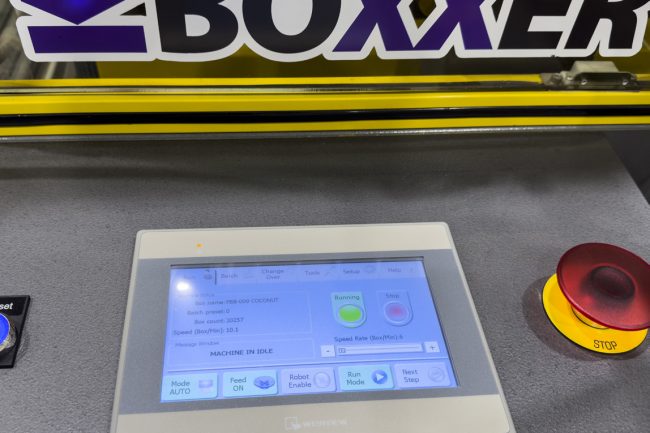

• The automatic BOXXER case erector developed by Paxiom’s Florida-based EndFlex LLC manufacturing sister company.

Designed to transfer the knock-down RSC or HSC blanks from the hopper magazine to the erecting station, the machine uses vacuum cups to pull the blanks out of the magazine, fold the two minor flaps into the case, and erect the case within a blink of an eye. Once done, the machine’s dual belt drives drive the erected case through the taping section, where the built-in tape head secures the bottom of the case and discharges the case towards the PKR Delta 1300 cell for loading. Outfitted with reliable SMC pneumatic components and an Omron PLC (programmable logic controller), the BOXXER case erector utilizes venture vacuum technology to ensure highly reliable and repeatable case-erecting at speeds of up to 18 cycles per minute, depending on the model.

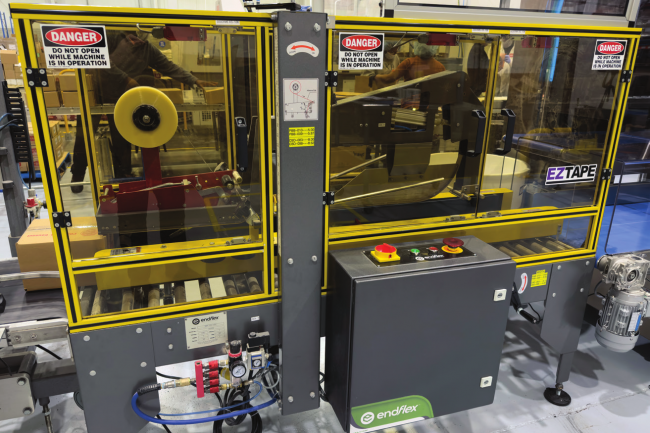

• The automatic EZTAPE CS-C50 uniform case closer and top-and-bottom sealer.

Also manufactured by EndFlex, the EZ TAPE CS-C50 is a user-friendly, fully adjustable machine incorporating dual masts to ensure optimal stability during the entire sealing process, along with heavy-duty side-belt drives to ensure perfectly squared cases and tight seals. Designed for quick changeovers and height adjustments without any special tools, the EZ TAPE CS-C50 features toolless tape heads for accurate and consistent sealing, with easily removable tape cartridges. According to PRANA’s vice-president of operations Julie Séguin, working with Paxiom to resolve the plant’s end-of-line packaging issues has already had a big impact on the stand-up pouch line’s efficiencies and productivity. “We have been able to completely optimize our team at that step of our process,” Séguin states. “Whereas we used to have a team of three people doing some very physical and repetitive work, were are now doing the job with an equivalent of 1.5-persons, with all the repetitive movement being completely eliminated. “As a result, we were able to relocate our team members elsewhere in our production to support our ongoing growth,” she points out. “This is a big plus at a time when the workforce market is so competitive.” Says Séguin: “At first, we were a bit reluctant about adding robotic technology to our facility because our team had never worked with this type of equipment. “However, this line is very lean and simple to operate,” Séguin states. “The system’s footprint fit perfectly into our available space,” she relates, “and Paxiom also provided full training and continuous support, which was an important part of our decision-making. “We met a couple of suppliers from the Montreal region to see what was available on the market,” Séguin confides, “and Paxiom ultimately offered what we were looking for.

“The process of validation of our product running on their equipment was very clear,” she relates, “and we worked closely with Paxiom through each step of assembling the line. “Moreover, Paxiom worked with us in providing the critical parts and user manuals we would need to do preventive maintenance on the equipment,” Séguin adds. “They trained our staff and were available at start-up and during our learning curve. “We have had excellent support from the entire Paxiom team,” says Séguin, adding that PRANA is currently exploring the possibility of purchasing an additional VFFS (vertical form-fill-seal) bagger from Paxiom. “With their complete packaging equipment portfolio, they will certainly be part of our future growth projects,” she states. Such ringing endorsement is naturally sweet music to Paxiom’s territory manager Strul, who says he thoroughly enjoyed the experience of working with a progressive and fast-growing customer like PRANA. “We were very happy to provide full support during their learning curve as they reached full ownership of the new system,” Strul says. “We educated the client on how to improve their overall system efficiency and to standardize their end-of-line packaging quality,” he adds. “I am certain they will achieve quick ROI (return-on-investment) thanks to reduced manpower requirements and having tangible data on their production efficiency going forward,” he points out. “PRANA quickly understood the areas they needed to improve to facilitate the integration with their existing line,” Strul concludes, “and they also invested the time to learn the new equipment. “As a result, they were able to run production on Day One and they have not stopped since.”