If you are in the food industry, you know how important it is to have a fast, reliable and hygienic packaging process. You need to ensure that your products are packed in the right quantity, quality and condition, while meeting the safety and regulatory standards. You also need to optimize your production costs and reduce your labor expenses.

That’s why you need automatic case packing. Automatic case packing is a process that uses robotic arms to pick and place your products into cases or cartons, without any human intervention. This way, you can increase your packaging speed, accuracy and consistency, while minimizing your labor requirements and risks of contamination.

But not all automatic case packing systems are created equal. Some use conventional robots that have limited flexibility, speed and precision. Others use Delta robots, which are the most advanced and efficient robots for case packing applications.

What are Delta robots and how do they work?

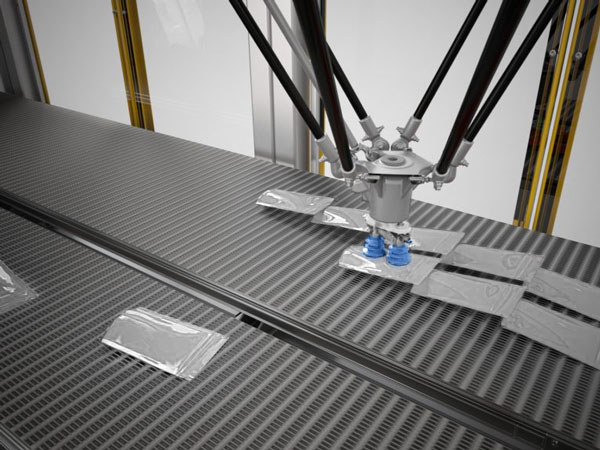

Delta robots are a type of parallel robot that have three arms connected to a triangular base. The arms can move up and down, and rotate around their joints, allowing the robot to reach any point within a spherical workspace. The robot also has a gripper or a suction cup at the end of its arms, which can pick and place different types of products.

Delta robots work by using a sophisticated software that controls the movement of the arms and the gripper. The software can communicate with a vision system that detects the position, orientation and shape of the products on a conveyor belt. The software can also adjust the speed and force of the robot according to the weight and fragility of the products.

Why are Delta robots the best technology for automatic case packing?

Delta robots have many advantages over conventional robots for automatic case packing. Here are some of them:

- Delta robots are faster and more agile. They can reach speeds of up to 200 picks per minute, and can handle products of different sizes, shapes and weights.

- Delta robots are more precise and accurate. They can place the products in the exact position and orientation required, and can avoid collisions and damages.

- Delta robots are more flexible and adaptable. They can switch between different products and packaging formats, and can handle changes in the production line.

- Delta robots are more compact and lightweight. They have a smaller footprint and a lower mass, which means they can be installed in tight spaces and consume less energy.

- Delta robots are more reliable and durable. They have fewer moving parts and joints, which means they require less maintenance and have a longer lifespan.

Why is eliminating human labor for repetitive motion jobs important to every company?

Eliminating human labor for repetitive motion jobs is not only beneficial for the company, but also for the workers. Here are some of the reasons:

- Eliminating human labor for repetitive motion jobs can reduce the production costs and increase the profitability. By using automatic case packing, you can save on labor wages, training, supervision, insurance and taxes. You can also reduce the waste, rework and downtime caused by human errors and fatigue.

- Eliminating human labor for repetitive motion jobs can improve the product quality and customer satisfaction. By using automatic case packing, you can ensure that your products are packed in a consistent, uniform and hygienic manner, meeting the highest standards of quality and safety. You can also increase your production capacity and delivery speed, meeting the growing demand of your customers.

- Eliminating human labor for repetitive motion jobs can enhance the worker safety and well-being. By using automatic case packing, you can reduce the exposure of your workers to physical and mental stress, injuries, illnesses and accidents. You can also free your workers from tedious and monotonous tasks, and allow them to focus on more creative and rewarding activities.

Why should you choose ValTara for your automatic case packing needs?

ValTara is a leading manufacturer and supplier of automatic case packing systems, using the latest Delta robot technology. We have over 20 years of experience in the food packaging industry, and we have a team of experts who can design, install and service your case packing solution. We offer a range of benefits for our customers, such as:

- ValTara offers customized and turnkey solutions. We can tailor our case packing systems to your specific needs, products and packaging formats. We can also integrate our case packing systems with other equipment, such as fillers, sealers, labelers and palletizers, to create a complete packaging line.

- ValTara offers high-quality and high-performance systems. We use the best materials, components and software for our case packing systems, ensuring their durability, reliability and efficiency. We also use the most advanced vision and control systems, ensuring their accuracy, flexibility and adaptability.

- ValTara offers competitive and affordable prices. We have a lean and streamlined production process, which allows us to reduce our overhead and operational costs. We also have a global network of partners and distributors, which allows us to offer our case packing systems at the best prices in the market.

- ValTara offers excellent and comprehensive service. We have a dedicated and professional customer service team, who can assist you with any questions, issues or requests. We also have a skilled and experienced technical service team, who can provide you with installation, training, maintenance and repair services. We also offer a warranty and a spare parts service, ensuring your peace of mind.

If you are looking for a way to improve your food packaging efficiency and cost effectiveness, look no further than ValTara. We have the best automatic case packing systems, using the best Delta robot technology. Contact us today and let us help you take your food packaging process to the next level.